- Business

Technologies

- Products

- Manufacturing Facilities

Technologies of Daito Chemix

1. Diazo compounds

We began with the manufacture and sale of synthetic dyes, further developing that technology for the manufacture of photosensitive materials and printing materials. Focusing on diazo compound synthesis, we later gained expertise in nitration reactions, amine reactions, oxidation-reduction reactions and halogenation reactions.

- Reduction

reactions Catalytic hydrogenation reactions using metal catalysts; reduction reactions and hydrazine reduction reactions using metal hydride compounds, sulfur compounds, etc.

- Oxidation

reactions Oxidation reactions using hydrogen peroxide, peracetic acid, chlorite, etc.

- Halogenation

Synthesis of acid chlorides using thionyl chloride; halogenation using NBS, bromine, phosphorous oxychloride, etc.

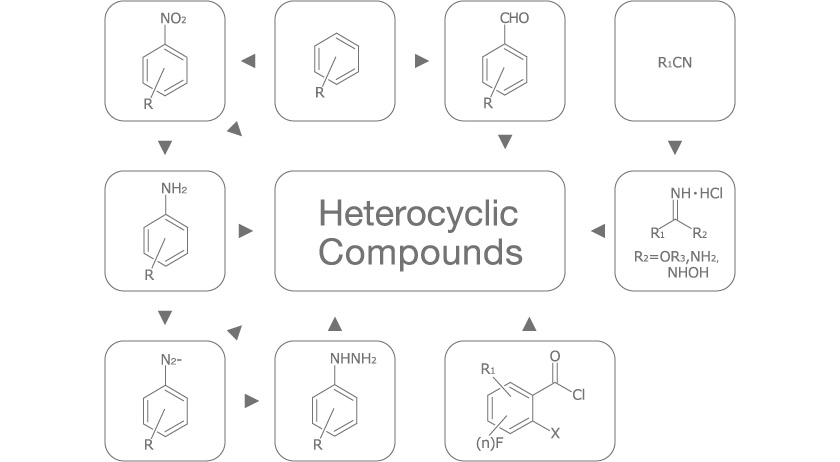

2. Heterocyclic compounds

Our technology for making photography materials was developed based on our dye manufacturing technology. We are highly experienced in the synthesis of diazo and various heterocyclic compounds.

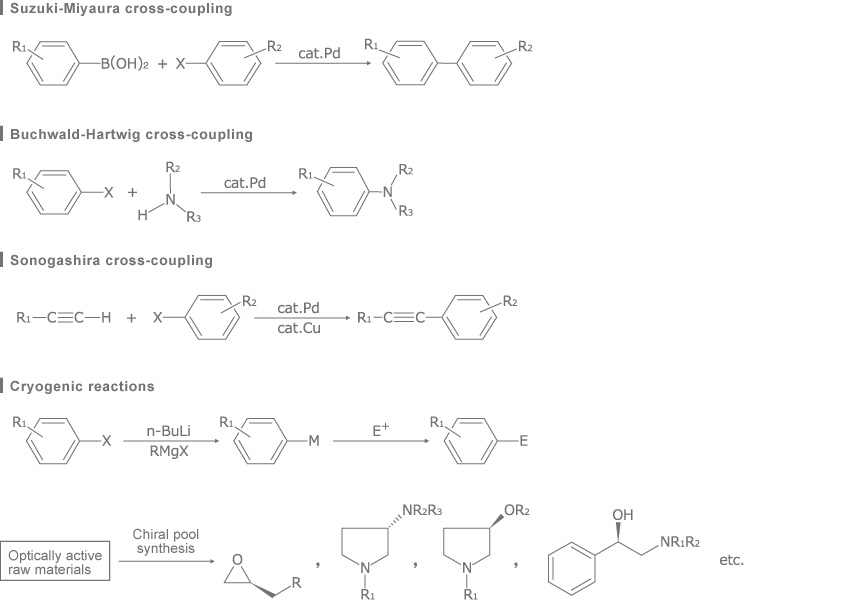

3. Other synthesis reactions

We make compounds for use as pharmaceutical intermediates, including pyrazole derivatives, quinoline compounds, thiazole derivatives, indazole derivatives, and indole derivatives. We have the equipment to perform multipurpose reactions such as Friedel-Crafts reactions, acylation and sulfonation, as well as cryogenic reactions at –90°C. We are capable of commercial-scale precision synthesis, such as using n-butyllithium and performing Grignard reactions, Suzuki-Miyaura cross-coupling reactions, and chiral pool synthesis. We have an excellent reputation among customers for production methods using multi-step reactions in a single pot. All our pharmaceutical intermediate manufacturing systems are GMP-compliant.

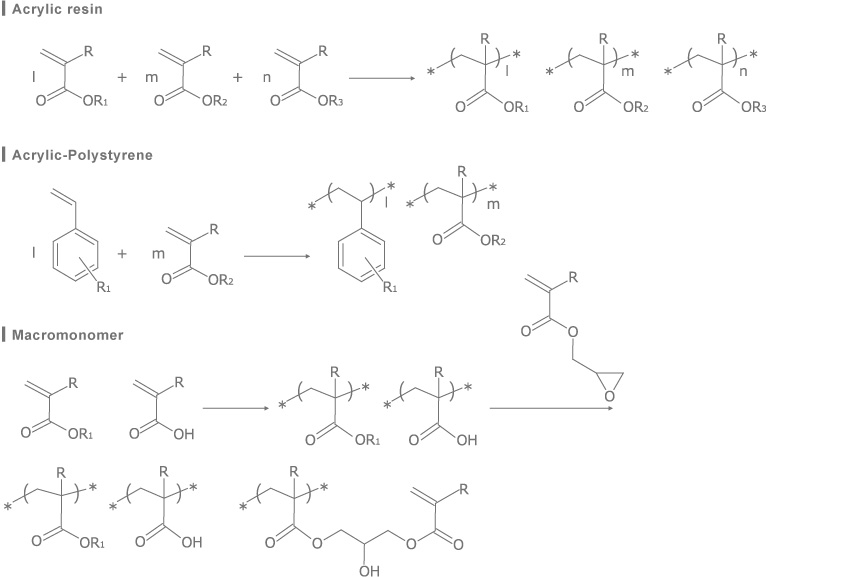

Special Technologies

We are adept at a variety of polymerization methods, including solution, emulsion, and suspension techniques. We can also do low metal content polymerization and make polymer compounds with controlled molecular weights for use as semiconductor resists. We have a fully equipped quality assurance system.

(Analytical device) GPC, ICP-MS, ICP-OES, AA, NMR, GC, DSC, Viscometer, etc

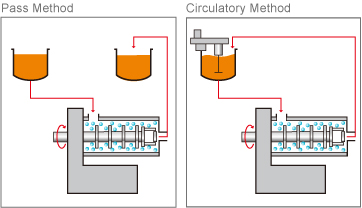

- Pulverization and dispersion technologies are key for producing both organic and inorganic compounds, and we can produce particles smaller than 100 nm. Our wet dispersion and nanoparticle dispersion machines enable water-based and organic solvent-based solid dispersion and pulverization using pass or circulation methods. We are adept at pulverization for film and ink materials, LCD panel fabrication materials, and inorganic materials for solar and secondary cells.